The eAFK HQ is the world’s most productive autodoff DTY machine for the high-end commodity market with a broad denier range (30 - 300den).

High efficiency on small space

With the automatic eAFK HQ DTY machine, Oerlikon Barmag offers the world’s most productive texturing machine. Furthermore, the new eAFK HQ simultaneously excels as a result of its extremely space-saving construction. With this, customers are able to texture their products on a machine with the smallest space requirements per position in the DTY market. At the same time, they benefit from the 50% increase in productivity compared to other texturing machines supplied by competitors.

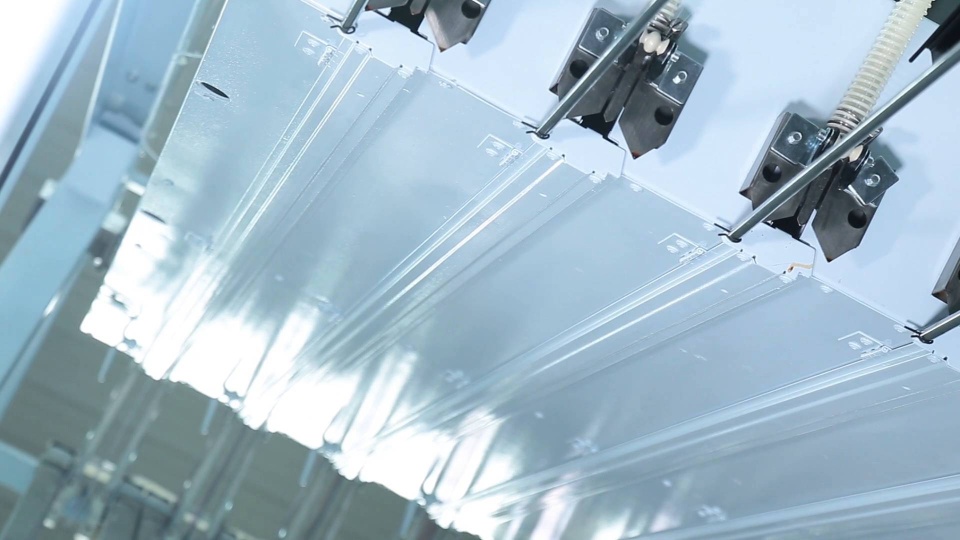

The eAFK HQ is designed with 12 sections, each with 48 positions. Compared to the eAFK machine an additional fourth level in the winding unit and extended sections increase the capacity of the machine to 576 positions – a world record! And all this with simultaneously considerably reduced energy consumption. The compact block heater lowers energy costs by reducing the radiated heat loss.

With the highest level of precision and gentler yarn handling, the new ATT traverse system with its optimized autodoff function ensures excellent package build with simultaneously outstanding doffing efficiency. Perfect package build ensures smooth further processing within the textile value chain. High productivity combined with a broad process window and robust machine design make the eAFK HQ a profitable investment for yarn manufacturers.