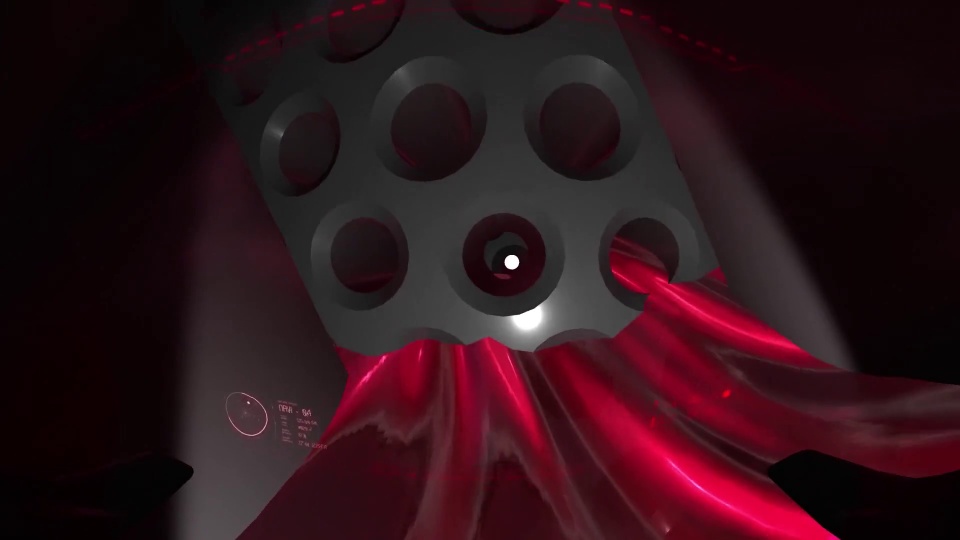

The principle behind manufacturing a thread is always the same: spinning pumps press the polymer melt through micro-fine spinnerets under extremely high pressure. The filaments created are then bundled into threads, drawn over godets and wound using a winder.

Precision processes for textile yarns

Reliably mastering this principle requires high-precision and simultaneously extremely sturdy technology. These machines are in operation day and night, year in, year out. The slightest fault in the spinning process cannot be subsequently corrected.

Oerlikon Barmag systems master the processes required for manufacturing textile and industrial yarns and spin the standard polymers polyester, polyamide 6 and 6.6 and polypropylene. Furthermore, we have also taken on the challenge of processing complex materials such as PTT, aramid, carbon fibers, glass fibers and similar.