Ever since manmade fibers were created, man has been attempting to give the smooth, synthetic filament a natural fiber-like character.

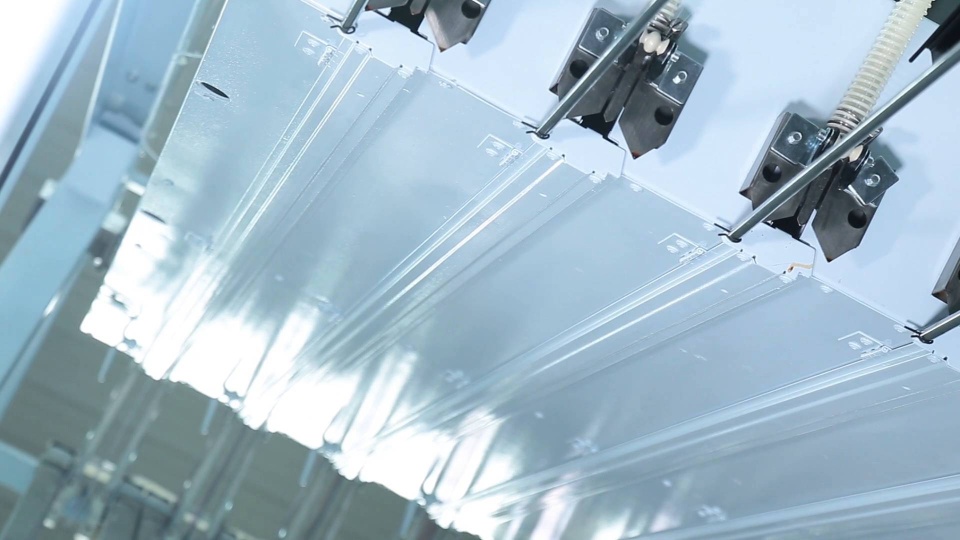

Texturing machines from Oerlikon Barmag

Texturing is a finishing step that transforms the POY supply yarn into DTY and hence into an attractive and unique product.

Apparel, home textiles, automotive – there are countless applications for textured yarns manufactured on Oerlikon Barmag machines. Correspondingly specific are the demands made on the yarns used.

During texturing, pre-oriented yarn (POY) is permanently crimped using friction. As a result, elasticity and heat retention are increased, the yarn receives a pleasant handle, while thermal conduction is simultaneously reduced.