Choose your country / language

Global

Americas

-

Argentina

Argentina

-

Brazil

Brazil

-

Canada

Canada

-

Mexico

Mexico

-

USA

USA

Europe

-

Austria

Austria

-

Belgium

Belgium

-

Czech Republic

Czech Republic

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Hungary

Hungary

-

Italy

Italy

-

Luxembourg

Luxembourg

-

Netherlands

Netherlands

-

Poland

Poland

-

Portugal

Portugal

-

Romania

Romania

-

Slovakia

Slovakia

-

Turkey

Turkey

-

United Kingdom

United Kingdom

Asia

-

China

China

-

India

India

-

Indonesia

Indonesia

-

Japan

Japan

-

Korea

Korea

-

Malaysia

Malaysia

-

Philippines

Philippines

-

Singapore

Singapore

-

Vietnam

Vietnam

PPD

Pulsed-Plasma Diffusion

Oerlikon Balzers’ PPD™ technology, which uses a combination of hydrogen, nitrogen and electricity but no hazardous chemicals to coat tools, sets a new industry standard by offering an environmentally friendly and less expensive alternative to the chrome-plating process used for wear protection treatment in the automotive industry.

What is PPD™?

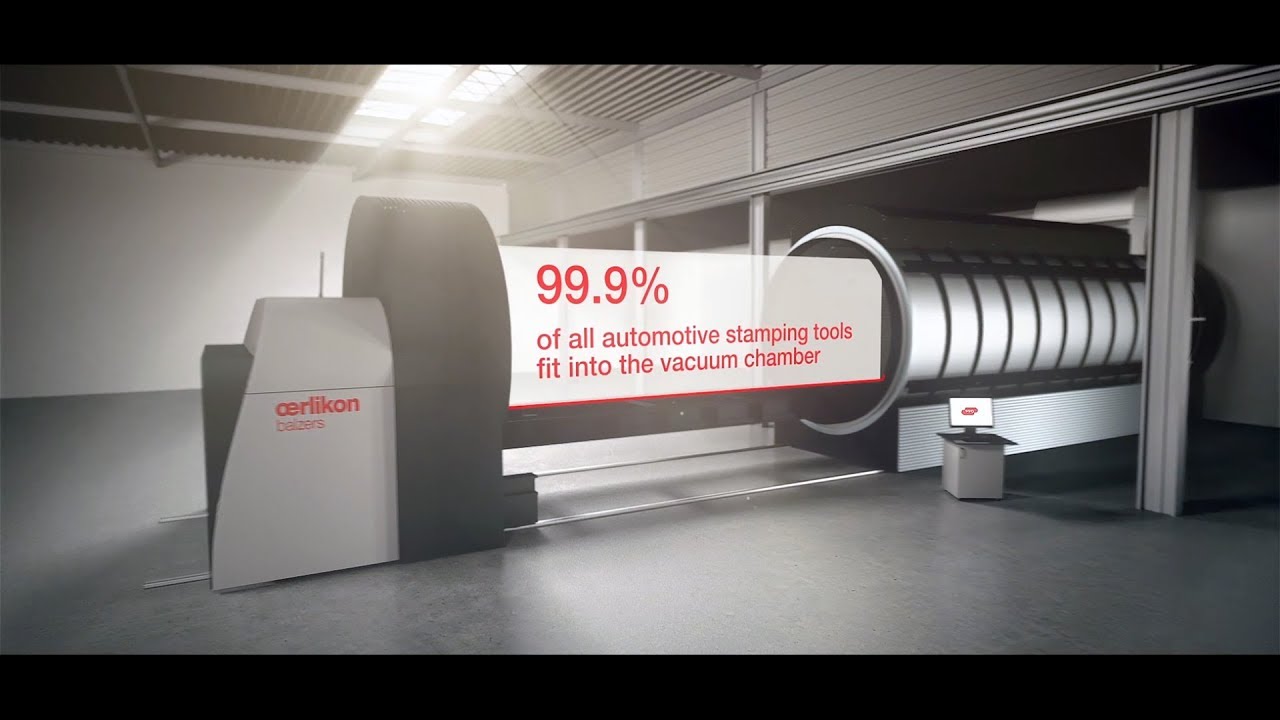

A step ahead of traditional nitriding processes, PPD™ is designed to protect automotive stamping tools from harsh production and working environments by endowing them with a wear resistant, hardened surface. Tool size is no issue, as even the largest tools in the industry fit into the PPD™ chamber with its 10m length and 40 metric tonne load capacity.

- Better quality parts through improved tool surface properties

- Faster project turnaround thanks to the huge capacity of the PPD™ vessel

- Cost savings through fewer scrapped parts and reduced tool maintenance

- Extended component service life

Typical PPD™ applications

- Automotive Stamping Tools