If you decide to start your own "in house" coating solution due to high external coating costs, Oerlikon Balzers offers an individual concept based on our many years of experience in our coating centers.

1 Cleaning

Clean surfaces are essential for coating adhesion. So Oerlikon Balzers invests a great deal of effort in surface preparation for PVD and offers multi-stage ultrasonic cleaning lines using aqueous alkaline baths with no environmentally harmful additives.

2 Pre-treatment

If additional pre-treatment is required, Oerlikon Balzers always uses the right technology. We offer various edge preparation and surface treatment technologies depending on your needs.

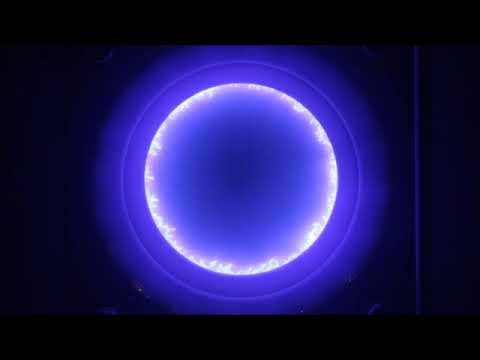

3 Coating

A broad range of coating technologies is available for almost unlimited cutting, forming, punching, metal die casting or plastics processing applications. Working in close collaboration with our customers around the world, our specialists are continuously opening up new applications. Customised coatings are available on request.

4 Post-treatment

Numerous methods are applied to give tools the finishing touches. Over the years, Oerlikon Balzers has gained the extensive experience needed to come up with the best solutions and equipment to meet your needs.

5 Quality control

The success of a coating also hinges directly on the condition and quality of the tool. We use visual and mechanical methods to assess the coating compatibility of incoming items and to determine coating quality. As our technologies are used in a wide range of industries, we are in the perfect position to offer consultation on which quality control resources you need.

6 After Sales

Technical support and advice via telephone, service hotline and email. Remote diagnostics and control for even faster troubleshooting. Professional on-site support for installations, upgrades, repairs and maintenance. Engineer dispatch within 24 hours. Service agreements. New and second-hand parts, as well as consumables. Upgrades, including the latest technologies and coatings. Standard and customer-specific graphite parts.